TESTING

SERVICES

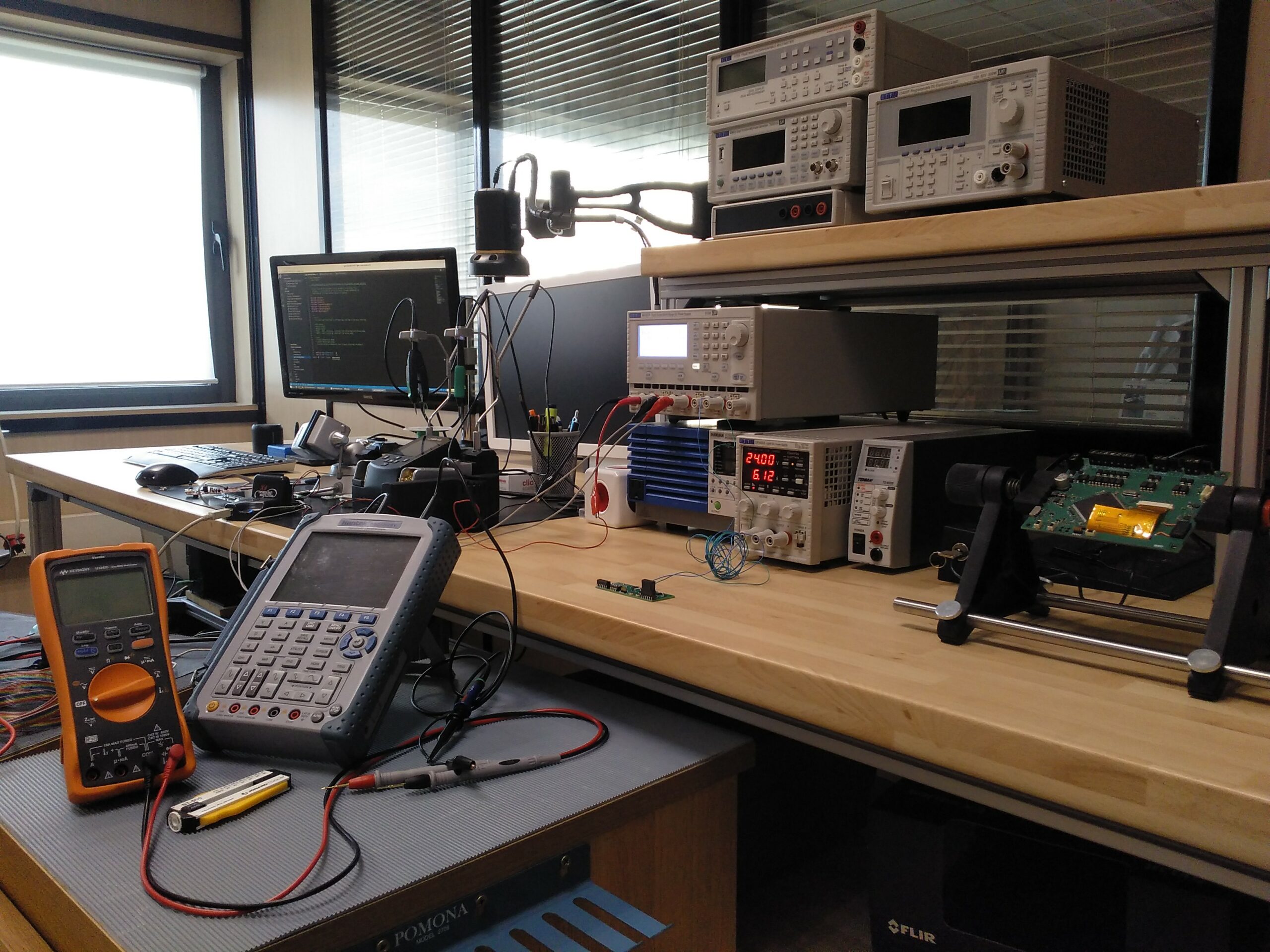

Testing

The plates that we manufacture go through a complete process of testing and validation, based on the most complete instrumentation and equipment, guaranteeing a very high quality of the final product.

At Eónica Solutions, we are fully committed to quality. That is why we have the main testing systems to guarantee the products manufactured.

Automatic Optical Inspection (AOI), X-ray Inspection, Functional Test, Aging Test, Weather Testing

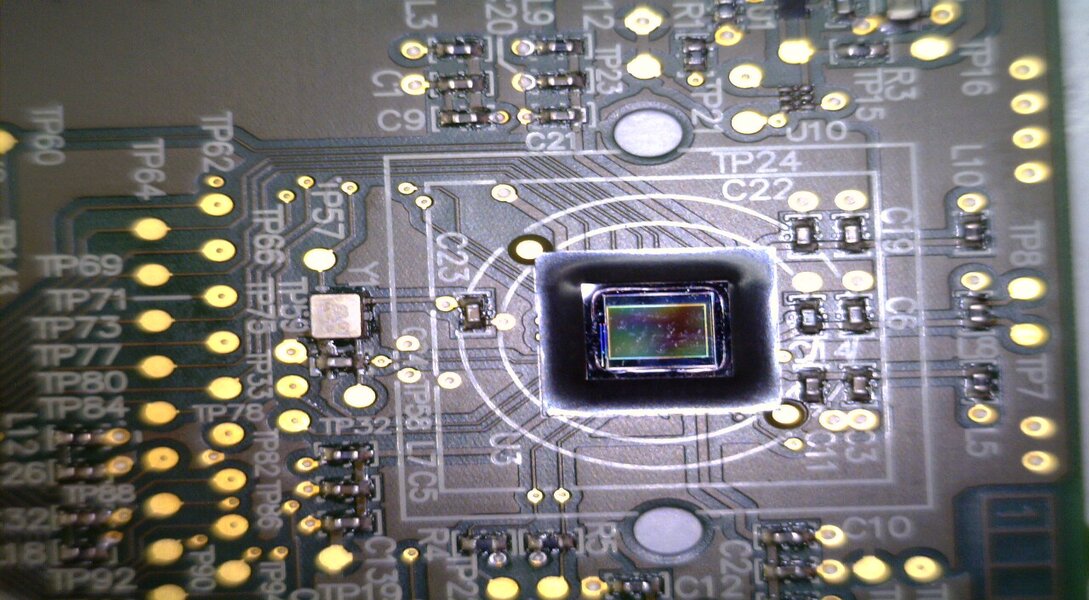

Functional Test

In the Test section we ensure exactly the correct operation of 100% of our products.

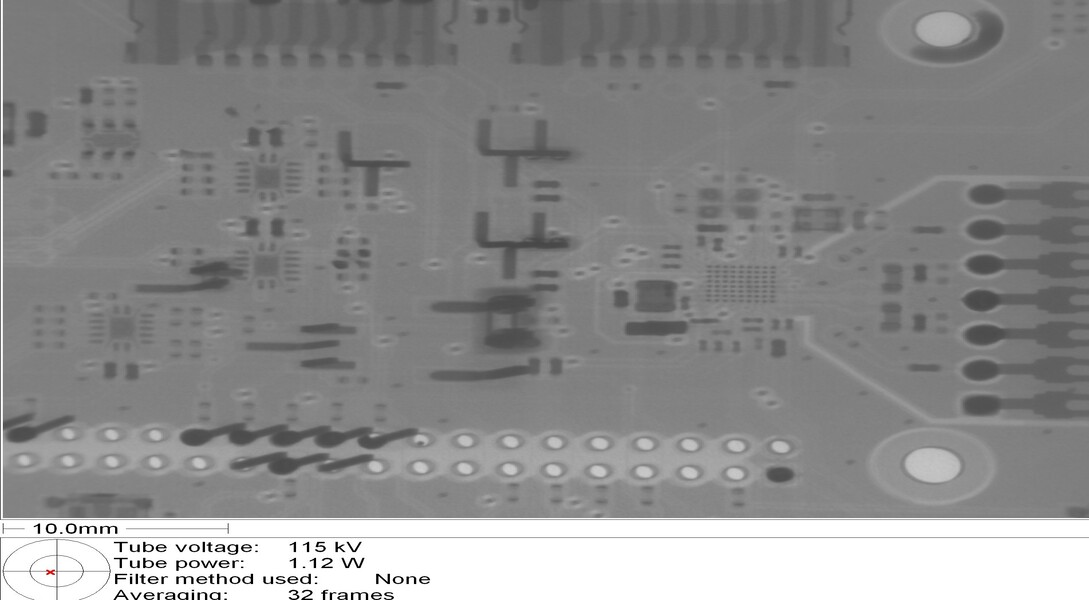

X-ray Inspection

The X-ray inspection allows us to detect non-visible defects and failures in the process, such as errors in the soldering of electronic components or detection of defects in the inner layers of circuits or under the components of the same that are not detectable with visual inspection.

Automatic Optical Inspection (AOI)

In today’s productions, as the size of the components is considerably reduced and the mounting density on the PCB increases, traditional visual inspection does not offer all the guarantees that error detection is complete.

The AOI has the ability to detect a wide variety of defects of a very diverse nature on the surface of the plate, incorrect components, missing components, components with an incorrect placement, presence of nodules, stains or scratches on the plate.

Therefore, all the electronic circuits and products manufactured by Eónica are functionally verified before being delivered.

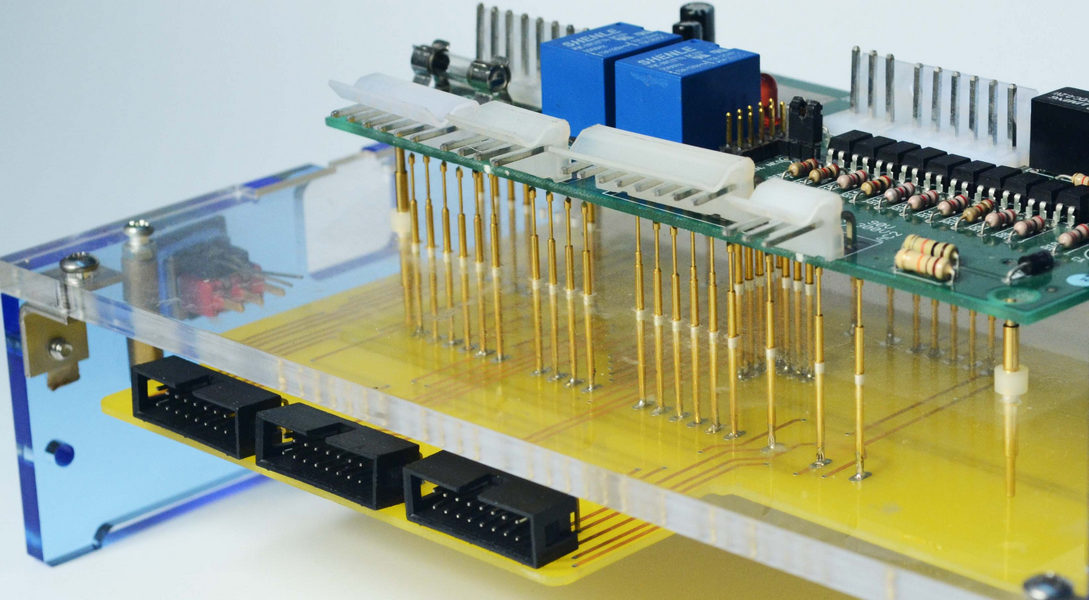

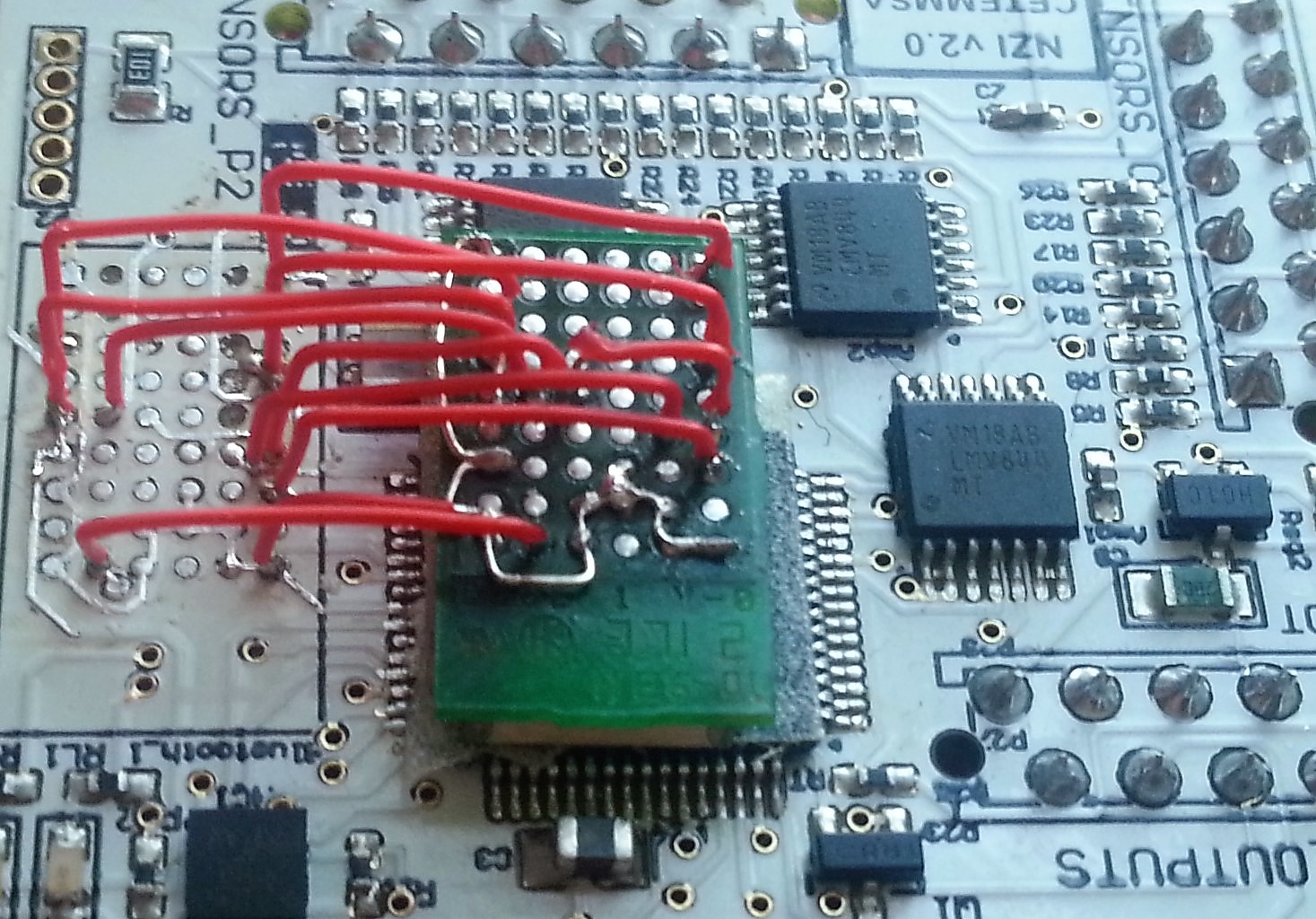

Reworks and special implementations

We offer service in the replacement and or rework of special components as well as reballing of BGA format components.

Express lead times

Delivery times: 48 to 72 hours

Other of our services

Consultancy

We will see to it that you carry out your projects successfully.

Logistics

Different services that facilitate the control of raw materials.

Electronic Design

Hardware and software design with your production in mind.

Electronic manufacturing

Manufacture of technological products.